- About Us

- Solutions

-

Products

Products

- Applications

-

News

News

-

Contact Us

Contact Us

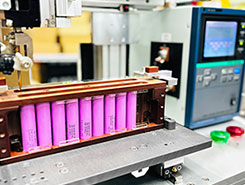

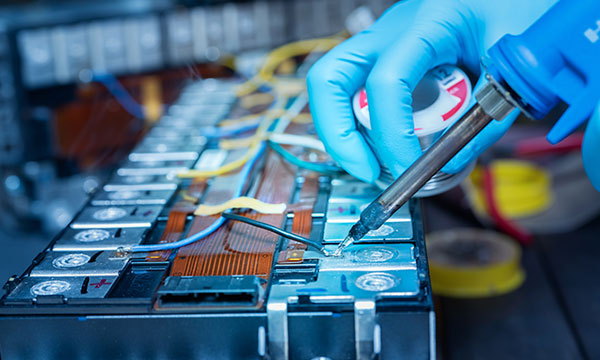

We propose integrated solutions tailored to the intended uses of

the products being developed, from cell selection to production of

battery packs, and also provide support with various international

certifications and reliability verification.

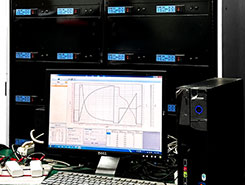

We provide the best quality and reliability by shipping our battery products after thorough testing using a variety of specialist equipment.

| Equipment | Spec | Q'ty |

|---|---|---|

| Cycler | Maccor | 1 |

| Drop Tester | 2.5cm | 1 |

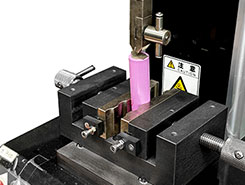

| Nail Tester | KSTM | 1 |

| Impact Tester | Kanatech | 1 |

| Chamber | -20 ~ 200℃ | 1 |

| Hot Box | ~ 200℃ | 1 |

| Vibration Tester | SPG | 1 |

| Micro Scope | Mitutoyo | 1 |